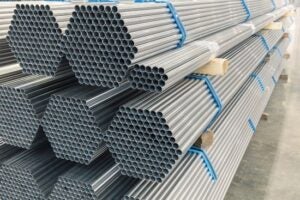

Meeting Philadelphia, PA’s Welded Steel Pipe Demands

The industrial sector relies on welded steel pipe solutions for construction, manufacturing, and infrastructure projects. At McKnight Steel & Tube Co., we serve the greater Philadelphia area with comprehensive welded steel pipe products that meet ASTM specifications and industry requirements. Whether you need standard carbon steel welded pipe or specialized stainless steel welded pipe, we ensure responsive service and reliable products to meet your project needs. Contact us today for tailored solutions, competitive pricing, and product support.

Key Features and Benefits of Welded Pipes

Welded steel pipe offers distinct advantages for industrial applications where cost-effectiveness meets performance requirements. Here are some of the key features and benefits of welded pipes:

- Cost Efficiency – Welded pipe typically costs less than seamless alternatives while maintaining adequate strength for numerous applications. This makes welded pipe an economical choice for projects with budget constraints.

- Availability – Welded pipe manufacturing processes allow for broader size ranges and more readily available inventory. Standard sizes are consistently stocked, reducing lead times for common specifications.

- Surface Quality – Advanced welding techniques create exceptionally smooth internal surfaces in welded stainless steel pipe. This precision finish ensures seamless flow and meets stringent sanitary standards, making welded pipe an excellent choice for high-purity applications.

- Dimensional Consistency – The manufacturing process for steel welded pipe maintains tight tolerances on outside diameter and wall thickness, ensuring compatibility with standard welded pipe fittings and installation procedures.

Types of Welded Pipes We Offer

Our facility stocks multiple categories of welded pipe to meet diverse industrial requirements. The types of welded pipes we offer include:

- Electric Resistance Welded (ERW) Pipe – This process uses electrical current to heat and fuse steel edges. Electric resistance welded pipe is commonly specified for structural applications, water systems, and general industrial use.

- Stainless Steel Welded Pipe – Manufactured to ASTM A312 standards, our welded stainless steel pipe availability includes grades 304, 304L, 316, and 316L. These products serve the chemical processing, food and beverage, and pharmaceutical industries.

- Carbon Steel Welded Pipe – Our carbon steel grades include A53 Grade B welded pipe for general structural and mechanical applications. These products meet requirements for construction, infrastructure, and industrial piping systems.

- Welded Pipe Fittings – Complete your piping systems with compatible fittings, including elbows, tees, reducers, and flanges. Our welded pipe fittings match the specifications and grades of our pipe.

- High-Frequency Welded Pipe – This welding process creates strong, consistent seams for demanding applications, producing welded pipe suitable for pressure services and structural uses.

The Welded Pipe Manufacturing Process

Welded pipe is manufactured through a multi-stage process that ensures quality and consistency. Here’s a breakdown of how our welded steel pipe is made:

- Forming – Steel coil is fed through forming rolls that gradually shape the flat material into a tube. The edges are brought together with precise alignment for welding.

- Welding – Electric resistance welding applies current directly to the steel edges, creating heat that fuses the material together. This process occurs at high speed, creating a continuous seam along the entire length of the pipe.

- Sizing and Shaping – After welding, the pipe passes through sizing rolls that ensure consistent outside diameter and roundness. This step is critical for maintaining dimensional tolerances.

- Testing and Inspection – Welded steel pipe undergoes various tests, including hydrostatic pressure testing, non-destructive examination of the weld seam, and dimensional verification to ensure compliance with ASTM standards.

- Finishing – Depending on specifications, welded pipe may receive additional treatments such as heat treatment, surface conditioning, or protective coatings before shipment.

Why Choose McKnight Steel & Tube Co.?

McKnight Steel & Tube Co. brings more than 70 years of experience serving the industrial community with reliable welded pipe solutions. Our approach focuses on meeting exact specifications. Here’s why procurers choose us for their pipe needs:

- Specification Compliance – We stock welded steel pipe that meets ASTM, ASME, and other industry standards. Our material certifications provide the documentation your projects require.

- Technical Support – Our team understands welded pipe applications and can assist with material selection, specification clarification, and compatibility questions.

- Processing Capabilities – Beyond standard welded pipe, we offer cutting, threading, and other processing services to deliver job-ready materials.

- Extensive Selection – We offer an extensive selection of metal shapes, including angles, channels, bars, rods, beams, and plates.

Contact Us Today to Request a Quote

McKnight Steel & Tube Co. is ready to support your projects with appropriate welded steel pipe solutions. We understand the importance of selecting the correct materials for your applications, and our team is here to guide you. Our inventory includes electric resistance welded pipe, various grades of stainless steel welded pipe, and a complete range of pipe fittings, to meet your detailed specifications. To ensure your project’s success, we provide material certifications, conduct dimensional verification for accuracy, and offer delivery to keep your projects consistently on track. Contact us today to request a detailed quote and discuss your welded pipe requirements with our team.

The Metal Experience

- In Business Since 1954

- Family Owned and Operated

- Material Test Reports Available

- Domestic and DFAR Compliant Material Available

- Company Trucks Deliver within a 120 mile radius of our Philadelphia location

- Delivery by Common Carrier Across the United States

- Close Working Relationships with an Assortment of Industry Professionals